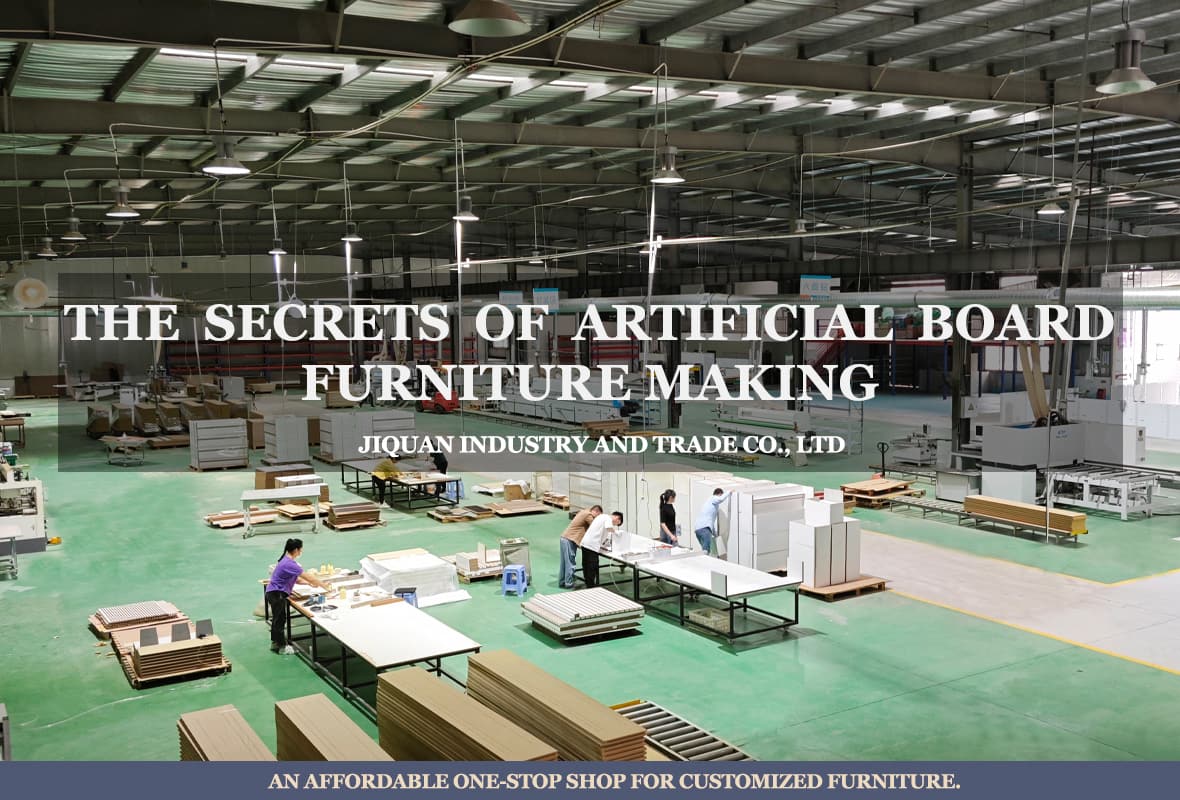

Inside the Furniture Factory: Unveiling the Secrets of Artificial Board Furniture Making

Artificial board furniture has become a crucial component of modern interior design, offering affordability, versatility, and sustainability. From stylish plywood tables to trendy particleboard cabinets, artificial board furniture adorns homes, offices, and commercial spaces worldwide. But what exactly happens inside the furniture factories where these pieces are made? Let’s take a closer look and reveal the secrets of artificial board furniture manufacturing.

1.Introduction to Artificial Board Furniture

Artificial board furniture, also known as engineered wood furniture, is crafted from various types of artificial wood products rather than solid wood. These products include plywood, particleboard, and medium-density fiberboard (MDF). The versatility of artificial boards enables furniture designers to create diverse shapes, sizes, and styles to meet varying preferences and space requirements.

2.The Manufacturing Process of Artificial Board Furniture

The process of manufacturing artificial board furniture typically involves the following steps:

Artificial Board Production: Raw materials are mixed with adhesive and compressed into boards of the desired size and thickness. This process often utilizes hot or cold pressing techniques to ensure the stability and strength of the boards.

Board Processing: Manufactured artificial boards undergo processing such as cutting, drilling, carving, edge banding, and trimming to prepare various components for furniture assembly.

Design and Assembly: Board components are assembled into furniture parts, including tabletops, drawers, doors, etc., according to design specifications and drawings.

Coating and Surface Treatment: Furniture receives coatings or surface treatments to enhance appearance, protect surfaces, and provide additional durability.

Quality Control and Packaging: Finished furniture undergoes quality inspections to ensure compliance with standards before being packaged for transportation and sale.

3.Types of Artificial Boards Used in Furniture Manufacturing

4.Artificial boards come in various types, each offering unique properties and advantages suitable for furniture production:

Plywood: Plywood is formed by bonding thin wood veneers together, providing strength and stability suitable for structural applications like tabletops and cabinet panels.

Particleboard: Particleboard is made from wood chips and particles bonded with resin under high pressure, offering a smooth and uniform surface ideal for painting or veneering.

Medium-Density Fiberboard (MDF): MDF is created by compressing wood fibers with resin into dense boards, offering excellent workability and dimensional stability for intricate furniture designs and decorative elements.

5.Advantages of Artificial Board Furniture

6.Artificial board furniture offers several advantages over traditional solid wood furniture:

Affordability: Artificial boards are often more cost-effective than solid wood due to lower manufacturing and material costs.

Versatility: The versatility of artificial boards allows designers to create customized furniture solutions tailored to specific functions and aesthetic preferences.

Uniformity: Artificial boards have uniform surfaces without natural wood defects, enhancing aesthetics and consistency in furniture manufacturing.

Environmental Sustainability: Artificial boards are often made from wood residues and recycled fibers, reducing the demand for natural forests and promoting sustainable forestry management.

Plasticity: Artificial boards can be easily processed into various shapes and sizes, enabling diverse furniture designs.

Challenges in Artificial Board Furniture Manufacturing

7.Despite its advantages, artificial board furniture production faces some challenges:

Quality Control: Maintaining consistent quality standards throughout the production process is essential to ensure the durability and longevity of artificial board furniture.

Environmental Concerns: The adhesives and chemicals used in artificial board production raise environmental issues related to emissions and waste disposal.

To gain a deeper understanding of the complex process of manufacturing artificial board furniture, let’s visit the JQ Furniture Factory.

Raw Material Storage: The factory has a vast material area storing Chinese E0-grade artificial boards. Each batch of boards undergoes SGS testing to ensure compliance with formaldehyde content and other chemical components.

Material Processing: JQ has implemented a fully integrated assembly line for the bespoke production of Artificial Board Furniture within the factory premises.

The process commences with the operation of a cold press machine located proximal to the material storage area, followed by sequential operations involving an automated board cutting machine and a computerized carving unit, facilitating the preliminary processing of the raw boards.

Subsequently, the machined boards are conveyed to an edge sealing station, where precise sealing techniques are applied. Following edge sealing, the boards undergo meticulous hole punching procedures.

Finally, the processed products are routed to designated areas for manual assembly and subsequent packaging. This delineates our meticulously designed and executed assembly line, orchestrating a seamless flow from the leftward quadrant to the rightward section of the factory floor plan.

8.Introduction to the Artificial Board Furniture Production Process

Cold Pressing of Materials: Raw materials mixed with adhesive are placed into a cold press machine. Under high pressure and temperature, the materials and adhesive are pressed into boards of the desired size and thickness. After pressing, the boards are removed and transferred to the next step.

Cutting of Materials: Manufactured artificial boards are cut into various sizes and shapes using saws or cutting machines to prepare components for furniture making.

Carving of Materials: According to design requirements, carving, drilling, or other processing is performed on the surface of artificial boards to create specific textures, patterns, or decorative effects. This may involve the use of CNC engraving machines or hand tools.

Edge Banding of Materials: Edge banding is applied to the edges of artificial boards to enhance edge durability and aesthetics. Common edge banding materials include PVC edge bands, ABS edge bands, or hot-melt adhesive.

Drilling of Materials: Drilling is conducted on artificial boards according to design requirements to facilitate assembly and connection in subsequent steps. Drilling is typically performed using CNC drilling machines or handheld drills.

Assembly of Materials: Various artificial board components are assembled and connected according to design requirements. Screws, glue, and other fixing materials are used to connect board components into the overall furniture structure.

Manual Detailing of Products: Manual detailing of products, such as edge trimming and surface polishing, is carried out to ensure product quality and appearance. This may involve the use of hand tools and mechanical equipment to achieve the desired surface smoothness and detail effects.

Clean Packaging of Products: Finished furniture is cleaned and packaged for transportation and sale. Packaging materials such as foam protection and cardboard boxes are used to protect products from damage during transportation and ensure product appearance is not affected.

Quality Assurance Measures: Before mass production, pre-production samples are produced to ensure the product’s structure is problem-free. JQ has set up four QC teams in the factory, who conduct a series of inspections, such as dimension, process, surface, at each production process to timely detect defective products and remove them from the production process to avoid wasting more time. Before packaging, JQ’s packaging supervisor and QC conduct trial packaging of products to ensure the packaging structure is safe and stable. Random inspections of bulk

9.Conclusion

Artificial board furniture has completely revolutionized the way we design and furnish living spaces, offering a perfect blend of affordability, versatility, and sustainability. By uncovering the secrets of artificial board furniture manufacturing, I believe you will gain a deeper understanding of artificial board furniture.

Share this article

Follow us

A quick overview of the topics covered in this article.

- 1.Introduction to Artificial Board Furniture

- 2.The Manufacturing Process of Artificial Board Furniture

- 3.Types of Artificial Boards Used in Furniture Manufacturing

- 5.Advantages of Artificial Board Furniture

- 7.Despite its advantages, artificial board furniture production faces some challenges:

- 8.Introduction to the Artificial Board Furniture Production Process

- 9.Conclusion

Latest articles

March 7, 2026

March 7, 2026